Full Directional Planetary Ball Mill

On basis of vertical planetary ball mill, the omnidirectional planetary ball mill adds the function of planetary disc overturning. While planetary disc and mill jars are doing planetary movement, they can also do 360 degree overturning in a stereo space to realize multi-directional and multi-dimensional movement of ball mill jars, and to improve degree of disordered movement of balls and materials. All material are ground inside the mill jars without dead angle, which makes grinding materials more uniform and finer. This kind of ball mill solves common issues such as sinking to the jar’s bottom and sticking to the jar’s wall.

QXQM series planetary ball mill has four ball grinding tanks installed on one disc. When the turn disc rotates, the mill pots revolve on their own axis and make 360 degree rotation. And the balls in the tanks grind and mix samples in high speed movement. The product can smash and blend various products of different materials and granularity with dry or wet methods. Minimum granularity of ground samples can be as small as 0.1 micron meter. It is widely used in the fields of Geology, Mining, Metallurgy, Electronics, Construction Material, Ceramics, Chemical Engineering, Light Industry Medicine, Environmental protection, and etc.

Features/Advantages

Features of Laboratory Full-directional Planetary Ball Mill

The machine makes 360 degree planetary movement without any dead corner, so the ground powder is much smaller and more even.

2. Gear transmission ensures to keep consistency and repeatability of experiment.

3. You may get four different powder samples at one time.

4. Variable frequency controlled and program controlled.

5. It solves the problems of materials sinking and sticking to the pot.

Advantages of Full-directional Planetary Ball Mill

Professional out looking design and industrial modeling of the ball mill shell with lean manufacturing make machine exquisite and fine. CNC processing technology is adopted for making machine-added parts, and precision gears with special materials are selected for transmission gears to ensure smooth, safe and low noise operation of the ball mill at high speed. Overturning motor has function of brake locking, which can stop overturn at any angle, it is safe and reliable. Ball mill is easy to be operated due to touch screen of micro-computer as its interface is simple and intuitive. This kind of ball mill can realize forward and backward alternating control, and has functions of timing and power-off memory.

A wide range of powder can be ground by our planetary ball mill with different mill jars and balls, such as ore powder, fluorescent powder, glass powder, pigment powder and so on. Following are some powder samples for your reference.

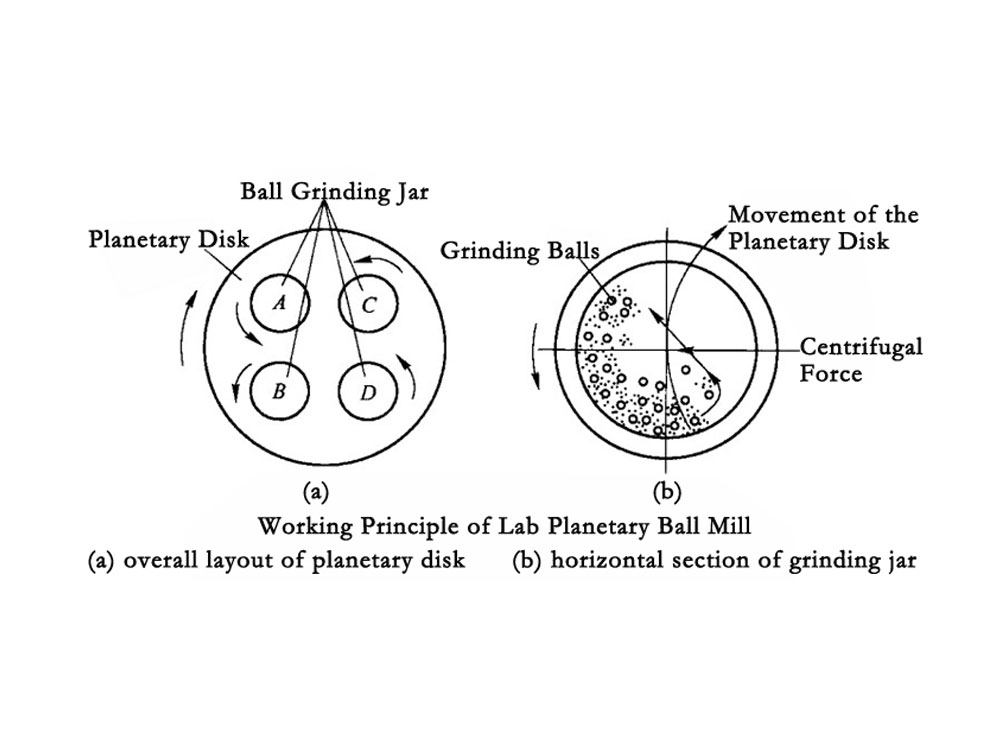

Work Principle

QXQM series planetary ball mill has four ball grinding tanks installed on one disc. When the turn disc rotates, the mill pots revolve on their own axis and make 360 degree rotation. And the balls in the tanks grind and mix samples in high speed movement. The product can smash and blend various products of different materials and granularity with dry or wet methods. Minimum granularity of ground samples can be as small as 0.1 micron meter. It is widely used in the fields of Geology, Mining, Metallurgy, Electronics, Construction Material, Ceramics, Chemical Engineering, Light Industry Medicine, Environmental Protection etc.QXQM series planetary ball mill has four ball grinding tanks installed on one disc. When the turn disc rotates, the mill pots revolve on their own axis and make 360 degree rotation. And the balls in the tanks grind and mix samples in high speed movement. The product can smash and blend various products of different materials and granularity with dry or wet methods. Minimum granularity of ground samples can be as small as 0.1 micron meter. It is widely used in the fields of Geology, Mining, Metallurgy, Electronics, Construction Material, Ceramics, Chemical Engineering, Light Industry Medicine, Environmental Protection etc.

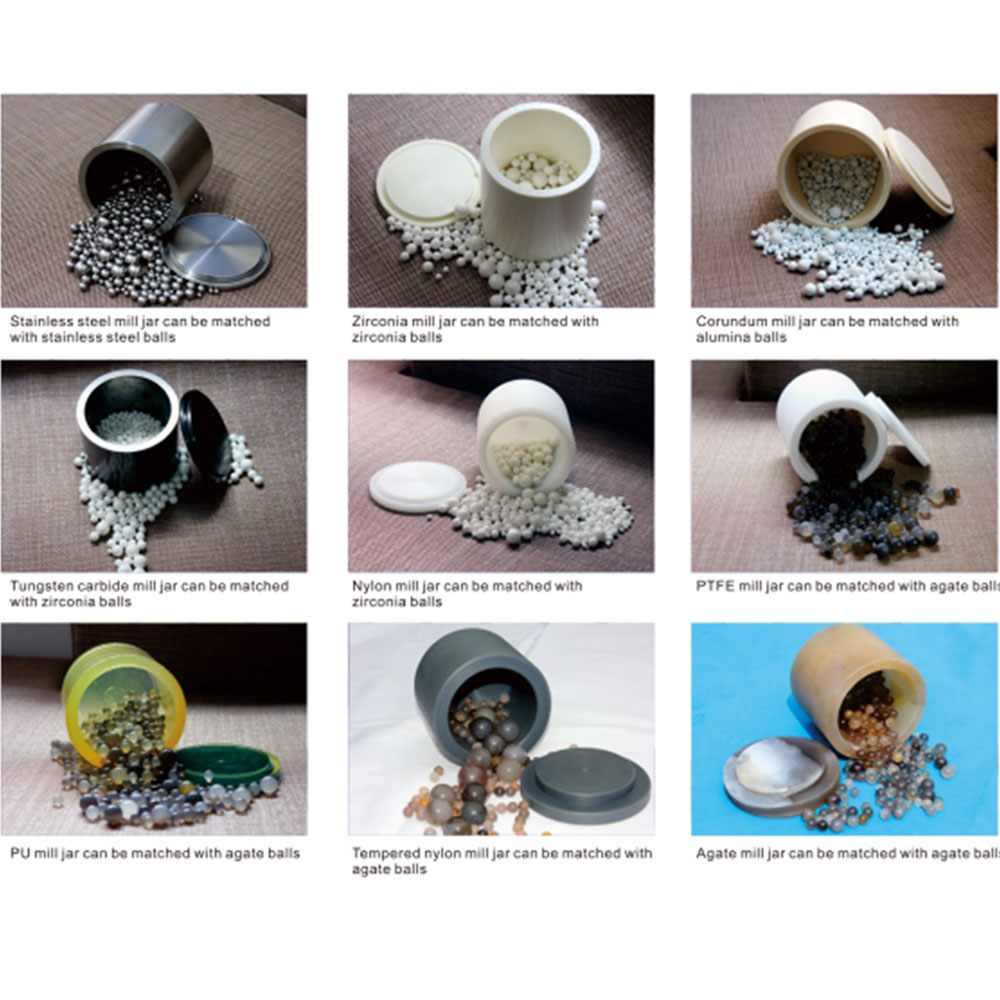

References for Matched Mill Jars and Balls

As a professional manufacturer and supplier of planetary ball mills, we provide all kinds of mill jars in full sizes covering 304 or 316 stainless steel mill jars, tungsten carbide mill jars, agate mill jars, corundum mill jars, zirconia mill jars, nylon mill jars, PU mill jars, PTFE mill jars and etc.

Production Specifications

Details Images

Company Profile

WELCOME TO VISIT OUR FACTORY

-- Our customers from over 50 countries and regions.

-- We have 20+ manufacturing experience and can provide custom design.

-- We provide engineer to help you with installation, training, our engineers are also available to install overseas if you need.

FAQ

Q: Are you a manufacturer of Planetary Ball Mill?

A: Yes, we are manufacturer of Planetary Ball Mill and have our own factory, located in Shicheng, Ganzhou, Jiangxi.

Q: What is the warranty of Planetary Ball Mill?

A: 1 year.

Q: will you help to install Planetary Ball Mill machinery?

A: If you need, we will have our technicians to assist you for installation.

Q:Could your company provide customized products?

A: Yes. OEM is welcome.

Our Service:

1. One year guarantee.

2. Sample testing.

3. our technician can design your project based on your information such as flow chart.

4. Engineer available for over seas installation and training.

5. after sale service, such providing spared parts.