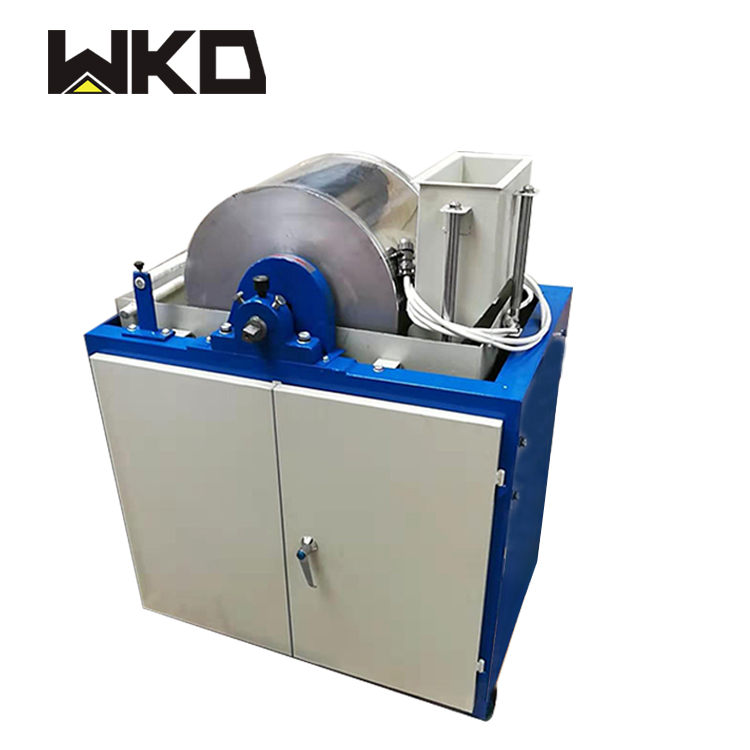

Laboratory Electromagnetic Wet Drum Magnetic Extractor

Drum separators are most common low intensity wet magnetic separators. They consist of a rotating non-magnetic drum containing three to six stationary magnets, either permanent or electromagnets, of alternating polarity. Magnetic particles are lifted by the magnets and pinned to the drum and are conveyed out of the field leaving the gangue particles. Water is introduced into the machine to provide a current which keeps the pulp in suspension. Three types of drum separators namely concurrent type, counter-rotation type and counter-current type are in use.Low Intensity Magnetic Separator

Concurrent type separators are used when clean concentrate is required from relatively coarse material such as heavy medium recovery systems. Counter-rotation type separators arc used in the roughing operation of larger tonnages. Counter-current type separators arc designed for finishing operation on relatively fine material.

Features

1. Electromagnet system and concurrent tank type;

2. Small in volume and light in weight;

3. Easy operation and convenient maintenance;

4. Uniform feeding of ores due to elevated agitating tank;

5. Wide range of magnetic intensity.

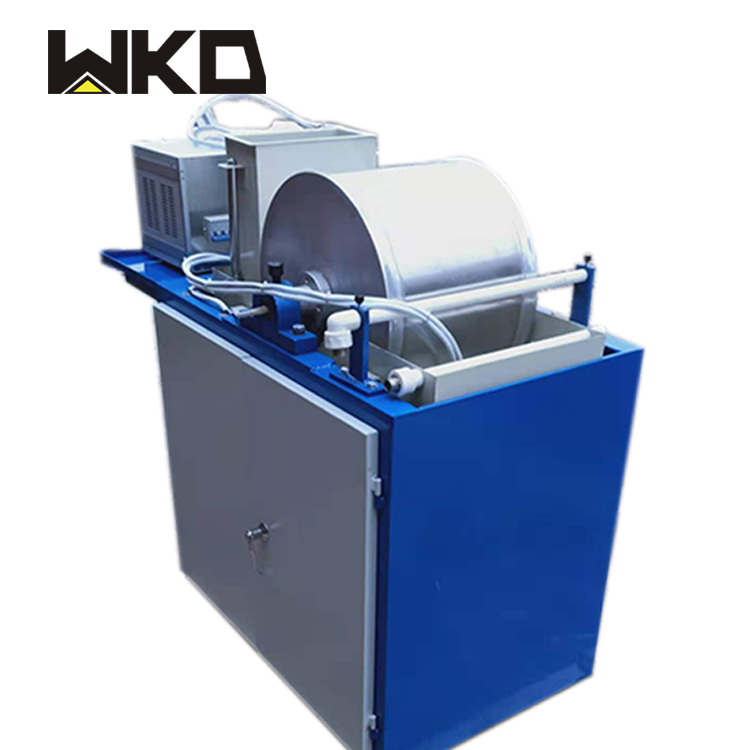

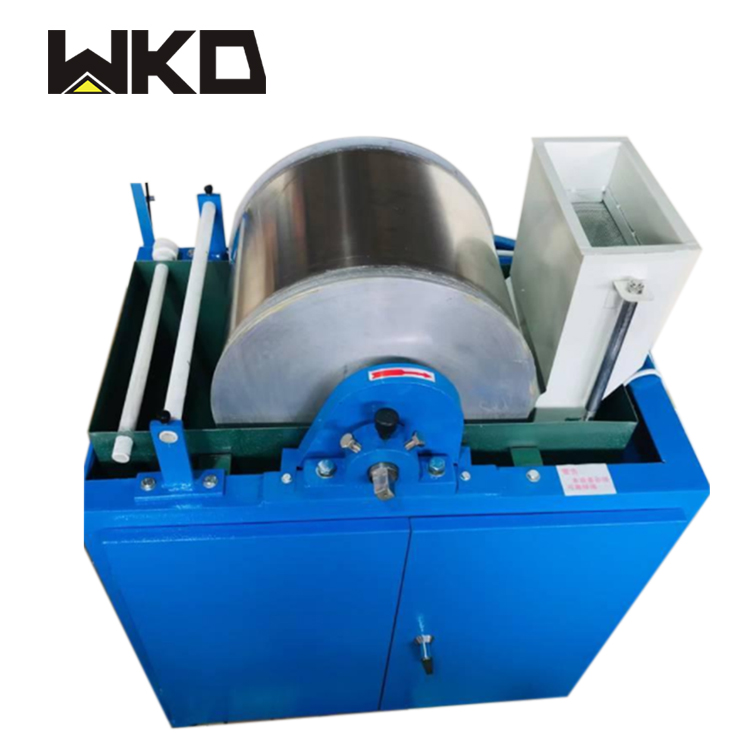

Working Principle

1.Frame: welded by angle steel, it is the supporting part of the whole machine.

2.Magnetic drum: It contains four exciting coils and a magnetic core, and an additional magnetic pole without an exciting coil is installed on the ore discharge side to facilitate unloading.These form sector and are fixed on the mandrel.The mandrel is fixed on the frame through bearing busing.The drum is made of non-magnetic aluminum and stainless steel.The connection of sector coil causes the alternation of magnetic field polarity on every magnetic palm.The magnetic particles turn 180°each time it passes one magnetic pole.Under the action of magnetic stirring,the quality of magnetic products can be improved.At one end of the mandrel is an extension of square structure which can be turned by wrench to get the magnetic pole inside the drum to rotate axially so that it can meet the requirements for the sorting of different types of ores.

3.Driving Device:The driving device is installed at one side of the bottom of the frame,In order to reduce the center of gravity of the whole machine, the transmission part is composed of three phase AC motors and worm gears and worm gearboxes. The output of the gearbox is transmitted to the drum through a chain, which drives the drum to rotate (the magnetic pole does not rotate with it) The rotation speed is 25 rpm, and the direction of the rotating force of the magnetic drum is the same as the feeding direction.

4.Ore Tank:It is welded by aluminum and stainless steel plate, and is fixed on the frame by screws; there is an overflow port on the feed side of the ore tank to maintain the liquid level, and a concentrate nozzle is provided at the lower part of the concentrate ore tank for connection of concentrates.

5.A water spray pipe: installed on the frame can be connected to the indoor water source for washing the concentrate on the magnetic drum; the water spray angle can be adjusted by rotating the water spray pipe.

6.Feeding Hopper:The box body is welded by stainless steel plate, its role is to ensure the uniformity when feeding.

Production Specifications

Company Profile

Victor is a large mineral processing manufacturer for 15 years history, with covering an area of 48,000 square meters

and 20,000 square meters for workshop, with various large modernized machinery facilities, professional R&D team and installationteam.

With 32% market share in China and the rest to overseas, already successfully exported to over 50 countries, such as USA, England,Australia, Brazil, Turkey, Italy, Russia, South Africa, Zimbabwe, Sudan, Ghana, Congo, Morocco, India,Indonesia, Malaysia, Philippines, North Korea, Mongolia, Vietnam, Thailand etc.

Our goal is to provide one-stop service for you and assist you to solve all problems from investment to his return in the field of mining, including the preliminary mineral analysis, mineral processing test, engineering design, equipment debugging and technical training etc..

We are expert especially at mining separating and lab mining plant, main products as below:

Gold trommel wash plant

Shaking table

Spiral chute separator

Centrifugal gold concentrator

Jig separator machines

Grinding and mill crusher

Flotation cell machine

Magnetic separator

Laboratory mining plant

To View More

FAQ

Q1:Are you a manufacturer of mining equipment?

A1:YES, with more than 15 years production & sales experience

Q2:Could your company help design mineral flow chart?

A2:YES, we have about 20 people team of technician and can design a whole set of processing line.

Q3:Can you provide sample testing?

A3:YES, we have mineral testing laboratory and can do sample testing.

Q4:For efficient communication, what information should you provide before quotation?

1) what's your processed material? if it's rock ore, do you have mineral report?

2) what's your capacity(tons per hours)?