Jaw Crusher

Jaw Crusher is the one of the most popular stone-crushing equipments in the world, Jaw crusher is ideally suitable for primary and secondary crushing. The highest anti-pressure strength of crushed material is 350Mpa. Our design and production are of high position both at home and abroad.

Jaw crusher can be used as the primary crusher to the medium size crushing of various ores and large-size materials , with the anti-crushing pressure of less than 350Mpa.And the jaw crusher can be divided into two kinds such as coarse and fine crushing .And this series of jaw crusher have complete specifications with the feeding particle size of 125mm~750mm.

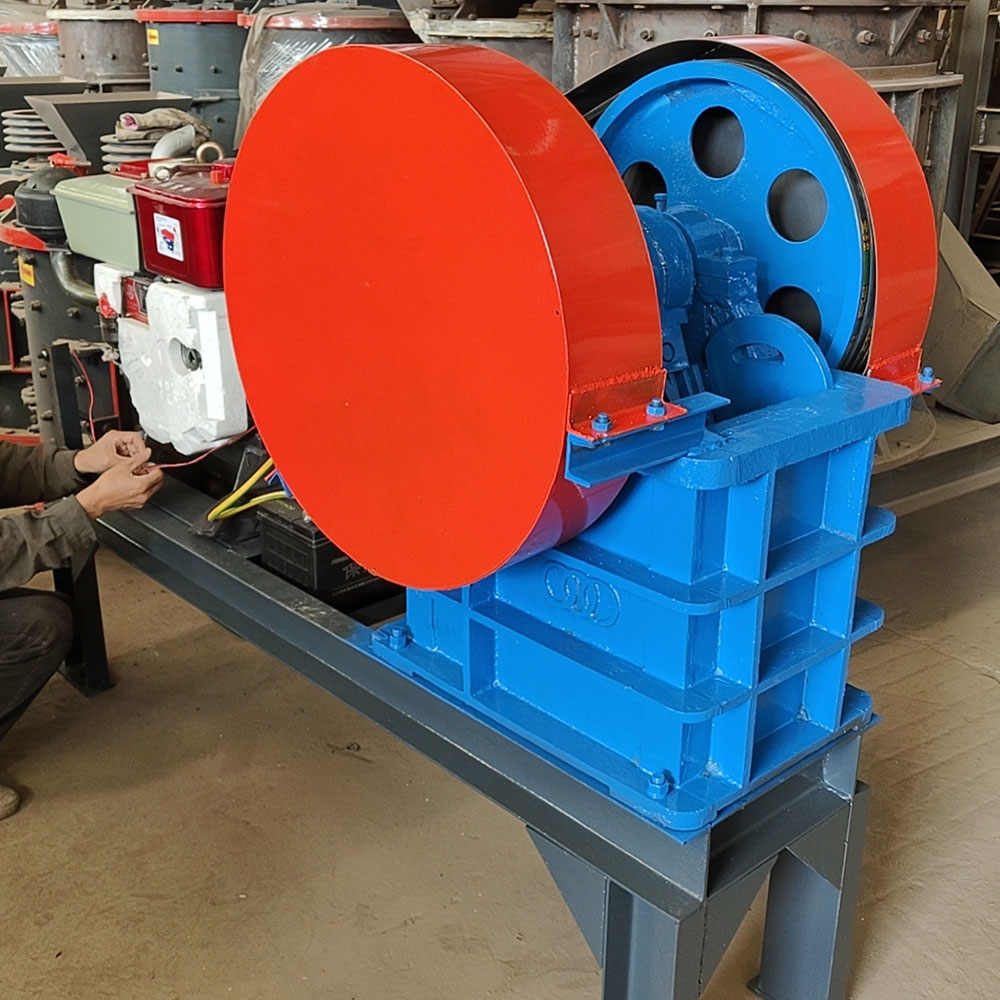

Detailed Images

Details about primary crushing, medium and fine crushing

1.Crushing: feed particle size is 300~900mm, the grain size is 100~550mm;

2.Pieces: feed particle size is 100~350mm, the grain size is 20~100mm;

3.Fine: feed particle size is 50~100mm, the grain size is 5~15mm.

Applicable

Features

a. High efficiency with uniform particle size.

b. Simple structure, and easy to operate, reduce the operation cost.

c. Crushing chamber is deep and has no dead space, which helps improve the feeding capacity and productivity.

d. Adjustment device of gasket type discharging end is reliable and convenient to use.

e. The discharging end has wide adjusting range which can increase the flexibility of our equipment.

f. Lubrication system is safe and reliable.

g. Over loading protection.

h. Accessories are convenient to replace, and little maintenance is needed.

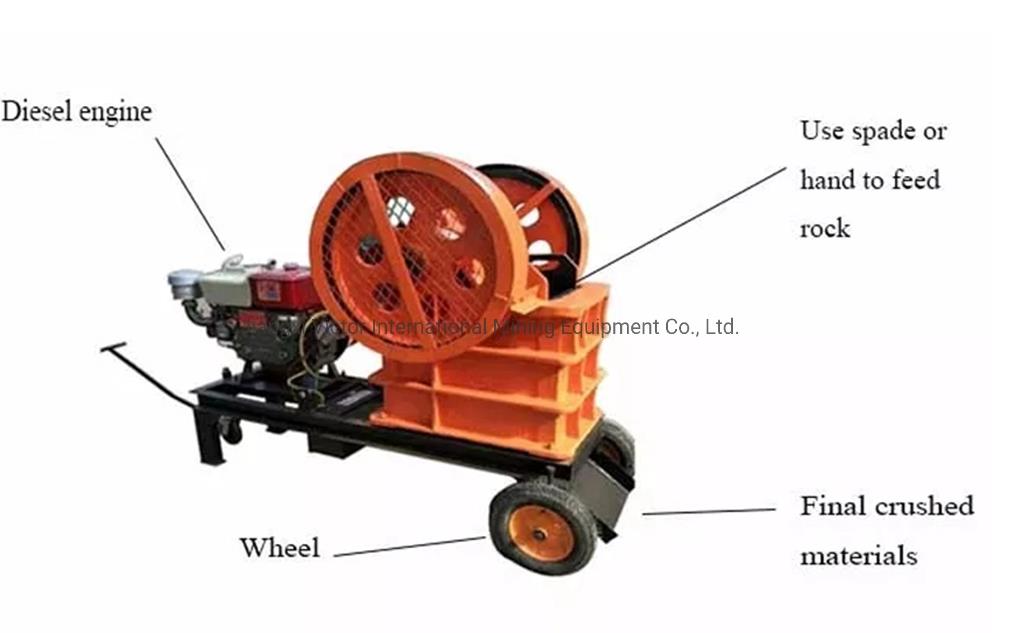

Working Principle

This jaw crusher uses motor as its power, through the motor's wheels, the eccentric shaft is driven by the triangle belt and slot wheel to make the movable jaw plate move by a regulated track. Therefore, the materials in the crushing cavity composed of fixed jaw plate, movable jaw plate and side-lee board can be crushed and discharged through the discharging opening.

Model | Feeding size(mm) | Max feeding size (mm) | Discharging Range size(mm) | Capacity (t/h) | Motor power (kw) | Weight (t) | Overall dimension (LxWxH)(mm) |

PE-250*400 | 250*400 | 210 | 20-80 | 5-20 | 15 | 2.8 | 1450x1315x1296 |

PE-400*600 | 400*600 | 340 | 40-100 | 16-60 | 30 | 6.65 | 1565x1732x1586 |

PE-500*750 | 500*750 | 425 | 50-100 | 40-110 | 55 | 11.73 | 1890x1916x1870 |

PE-600*900 | 600*900 | 500 | 65-180 | 80-180 | 55-75 | 16.13 | 2305x1840x2298 |

PE-750*1060 | 750*1060 | 630 | 80-180 | 110-320 | 90-110 | 28 | 2450x2472x2840 |

PE-800*1060 | 800*1060 | 680 | 100-200 | 140-340 | 90-110 | 30 | 2610x2556x2800 |

PE-870*1060 | 870*1060 | 750 | 170-270 | 180-360 | 90-110 | 31.22 | 2660x2556x2800 |

PE-900*1060 | 900*1060 | 780 | 200-290 | 200-380 | 90-110 | 31 | 2690x2556x2800 |

PE-900*1200 | 900*1200 | 780 | 95-225 | 220-450 | 110-132 | 49 | 3335x3182x3025 |

PE-1000*1200 | 1000*1200 | 850 | 195-280 | 280-550 | 110-132 | 51 | 3435x3182x3025 |

PE-1200*1500 | 1200*1500 | 1020 | 150-300 | 400-800 | 160-220 | 100.9 | 4200x3732x3843 |

PE-1500*1800 | 1500*1800 | 1200 | 210-360 | 525-1120 | 280-335 | 132 | 5100x4700x4300 |

PEX-150*750 | 150*750 | 120 | 18-48 | 8-25 | 15 | 3.5 | 1380x1658x1025 |

PEX-250*750 | 250*750 | 210 | 25-60 | 13-35 | 30 | 4.96 | 1545x1667x1330 |

PEX-250*1000 | 250*1000 | 210 | 25-60 | 16-52 | 30-37 | 6.5 | 1530x1992x1380 |

PEX-250*1200 | 250*1200 | 210 | 25-60 | 20-61 | 37-45 | 8.52 | 1900x2192x1430 |

PEX-300*1300 | 300*1300 | 250 | 20-90 | 25-95 | 55-75 | 12.6 | 1750x2320x1724 |

PEX-350*1200 | 350*1200 | 300 | 70-140 | 25-120 | 75 | 12.35 | 2162x2220x1723 |

Company Information

Victor is a large mineral processing manufacturer for 15 years history, with covering an area of 48,000 square meters and 20,000 square meters for workshop, with various large modernized machinery facilities, professional R&D team and installation team.

With 32% market share in China and the rest to overseas, already successfully exported to over 50 countries, such as USA, England, Australia, Brazil, Turkey, Italy, Russia, South Africa, Zimbabwe, Sudan, Ghana, Congo, Morocco, India,Indonesia, Malaysia, Philippines, North Korea, Mongolia, Vietnam, Thailand etc.

Our goal is to provide one-stop service for you and assist you to solve all problems from investment to his return in the field of mining, including the preliminary mineral analysis, mineral processing test, engineering design, equipment debugging and technical training etc..

We are expert especially at mining separating and lab mining plant, main products as below:

Gold trommel wash plant

Shaking table

Spiral chute separator

Centrifugal gold concentrator

Jig separator machines

Waste recycling machine

Grinding and mill crusher

Flotation cell machine

Magnetic separator

Laboratory mining plant

Our Services

1. One year guarantee.

2. Sample testing.

3. our technician can design your project based on your information such as flow chart.

4. Engineer available for over seas installation and training.

5. after sale service, such providing spared parts.

FAQ

Q: Are you a manufacturer of jaw crusher?

A: Yes, we are manufacturer of jaw crusher and have our own factory, located in Shicheng, Ganzhou, Jiangxi.

Q: What is the warranty of jaw crusher?

A: 1 year.

Q: will you help to install jaw crusher machinery?

A: If you need, we will have our technicians to assist you for installation.

Q:Could your company provide customized products?

A: Yes. OEM is welcome.