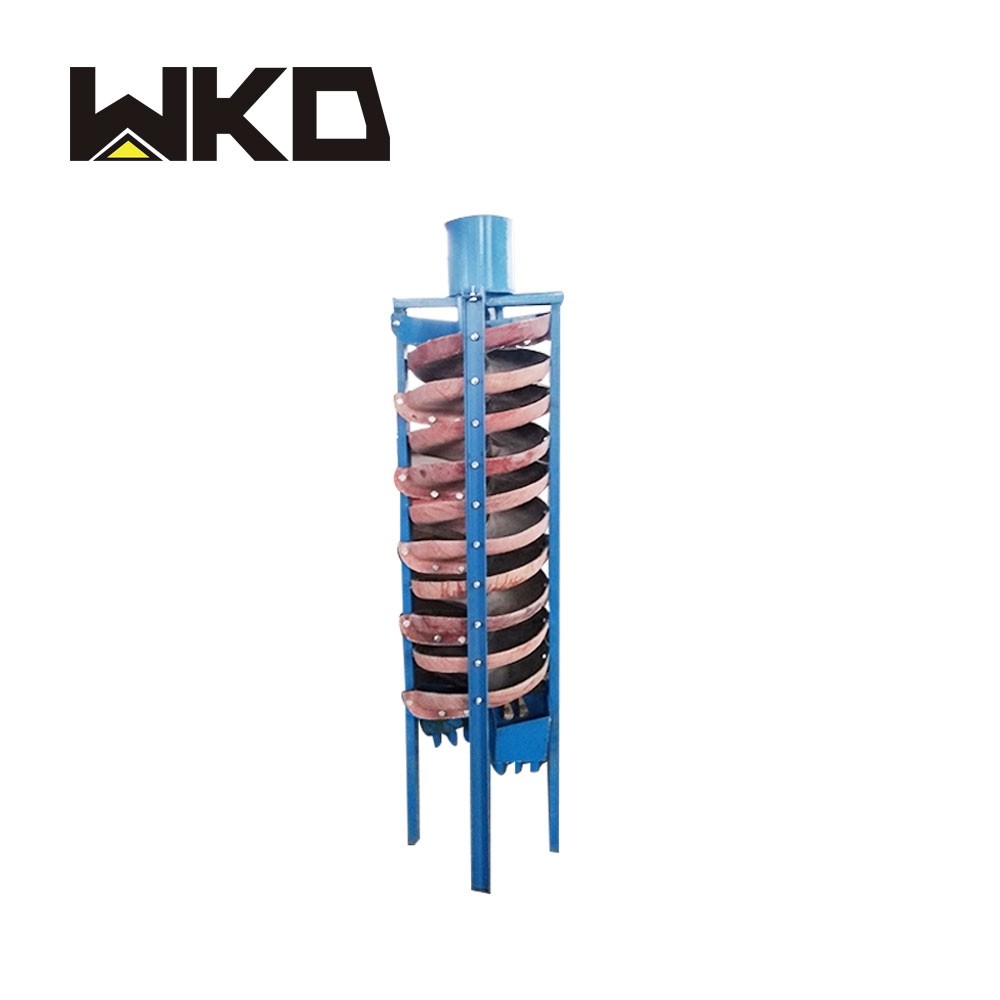

Spiral Chute

Spiral chute, a new gravity separation machine, applicable to processing iron, tin, tungsten, tantalum, niobium, gold, coal and other metal separation from particle size 0.6mm to 0.05mm.

It has been used in to enrichment the particle size 0.3-0.02 millimeters fine grain like iron, tin, chromite,ilmenite,tungsten, zinc, tantalum-niobium, gold, coal, monazite, rutile, zircon and other low-grade ores. The non-metallic minerals which have a big enough specific gravity difference.Spiral chute, a new gravity separation machine, applicable to processing iron, tin, tungsten, tantalum, niobium, gold, coal and

other metal separation from particle size 0.6mm to 0.05mm.

It has been used in to enrichment the particle size 0.3-0.02 millimeters fine grain like iron, tin, chromite,ilmenite,tungsten, zinc, tantalum-niobium, gold, coal, monazite, rutile, zircon and other low-grade ores. The non-metallic minerals which have a big enough specific gravity difference.

Features

1. Reasonable structure and small occupation area

2. High recovery, high efficiency, and precise separation

3. Non-required power

4. Light in weight, anti corrosion, rust and wear resistant

5. Simple installation and Minimal maintenance requirements

6. Low operating cost and long working life

7. Reliable running with minimal operator attention

8. Strong adaptability to fluctuation of feeding amount, density, size and grade

9. The surface of corundum forms strong friction the concentration effect surpass plastic surface.1. Reasonable structure and small occupation area

2. High recovery, high efficiency, and precise separation

3. Non-required power

4. Light in weight, anti corrosion, rust and wear resistant

5. Simple installation and Minimal maintenance requirements

6. Low operating cost and long working life

7. Reliable running with minimal operator attention

8. Strong adaptability to fluctuation of feeding amount, density, size and grade

9. The surface of corundum forms strong friction the concentration effect surpass plastic surface.

Working Principle

As larger and heavier particles sink to the bottom of the sluice faster and experience more drag from the bottom, they travelslower, and so move towards the center of the Spiral Chutes. Conversely, light particles stay towards the outside of the spiral, with the water, and quickly reach the bottom. At the bottom, a "cut" is made with a set of adjustable bars, channels, or slots, separating the low and high density partsAs larger and heavier particles sink to the bottom of the sluice faster and experience more drag from the bottom, they travel slower, and so move towards the center of the Spiral Chutes. Conversely, light particles stay towards the outside of the spiral, with the water, and quickly reach the bottom. At the bottom, a "cut" is made with a set of adjustable bars, channels, or slots, separating the low and high density parts

Product Specifications

Details Images

Company Profile

Victor is a large mineral processing manufacturer for 15 years history, with covering an area of 48,000 square meters

and 20,000 square meters for workshop, with various large modernized machinery facilities, professional R&D team and installationteam.

With 32% market share in China and the rest to overseas, already successfully exported to over 50 countries, such as USA, England,Australia, Brazil, Turkey, Italy, Russia, South Africa, Zimbabwe, Sudan, Ghana, Congo, Morocco, India,Indonesia, Malaysia, Philippines, North Korea, Mongolia, Vietnam, Thailand etc.

Our goal is to provide one-stop service for you and assist you to solve all problems from investment to his return in the field of mining, including the preliminary mineral analysis, mineral processing test, engineering design, equipment debugging and technical training etc..

We are expert especially at mining separating and lab mining plant, main products as below:

Gold trommel wash plant

Shaking table

Spiral chute separator

Centrifugal gold concentrator

Jig separator machines

Grinding and mill crusher

Flotation cell machine

Magnetic separator

Laboratory mining plant

To View More

FAQ

Q1:Are you a manufacturer of mining equipment?

A1:YES, with more than 15 years production & sales experience

Q2:Could your company help design mineral flow chart?

A2:YES, we have about 20 people team of technician and can design a whole set of processing line.

Q3:Can you provide sample testing?

A3:YES, we have mineral testing laboratory and can do sample testing.

Q4:For efficient communication, what information should you provide before quotation?

1) what's your processed material? if it's rock ore, do you have mineral report?

2) what's your capacity(tons per hours)?